EQMS Blog

Five Steps In Continuous Improvement Process For Your Business

The current economic downturn has affected various sectors, including some that earlier thought to be recession proof. Fierce competition and constantly changing circumstances compel every company to focus their energies on sustaining business and improving productivity. To overcome these challenges, some organisations have taken short term measures such as restructuring or downsizing.

However, such measures do not necessarily equate to success during a recession. If businesses are to prosper, they must find and implement real methods of improving quality to gain the competitive edge in a declining economy. One proven way to gain the all-important competitive edge is to embed a culture of continuous improvement in the organisation.

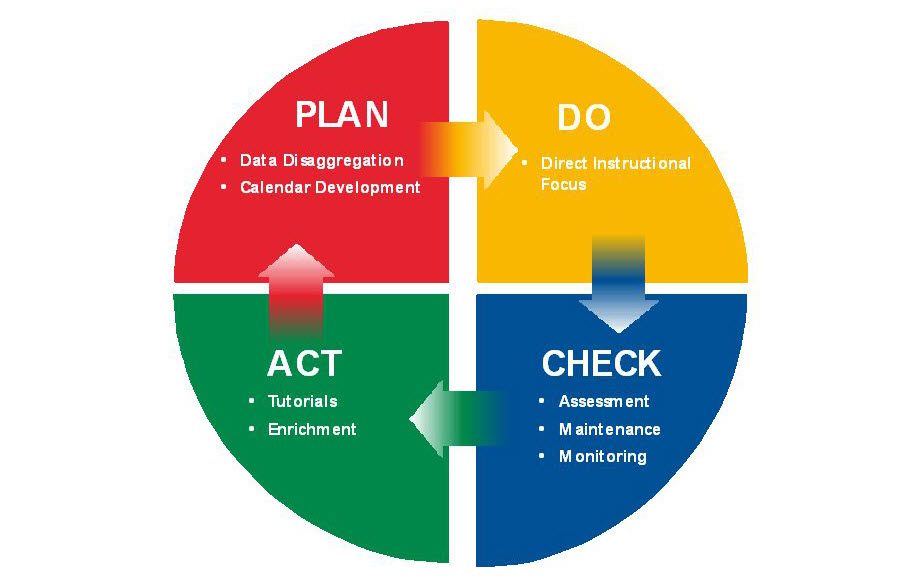

Continuous improvement is a process oriented approach to manage the business in which the process are constantly evaluated and in the light of their efficiency, effectiveness and flexibility. Implementation of continuous improvement methodologies can help companies sharpen their focus on costumers and process to minimize inefficiencies. With various methodologies and systems available in the market, selection of the right one is driven by the needs of the organisation and its capacity to implement such strategies. Though there are many approaches to beginning a continuous improvement process, few have proven successful over time.

Let’s continue with reviewing some of the steps in continuous improvement process.

Steps in Continuous Improvement Process

Quality Circles

This concept incorporates small voluntary groups who are trained to identify, analyse and solve work related problems. They then present their solutions to the management team in order to improve performance of the organisations and motivate employees. One of the tools commonly used for making the quality circles successful are process mapping. Process mapping is used to mad new and existing processes in order to create insightful analysis. This analysis provides an objective view of each process, which, in doing so, helps illuminate the goals and output. With process maps, your employees can get the “big picture” and use it to plan a continuous improvement path.

Integrate Continuous Improvement into a Culture of Strategic Execution

Continuous improvement and change management go hand in hand as outlined below. There is prep work to be done in order to create the basis for sustaining a program that is designed to support the long terms needs of the company. High performance culture requires a clear strategy. Clarify your vision, mission and values and set objectives throughout the organisation. Work on your culture with a high focus on communication as the employees within the organisation is an important consideration for continuous improvement. They need to have the right direction, the right tools and the right support.

Total Quality Management (TQM)

This is a management approach focused on ensuring quality of both process and product. Amongst the various methods used to implement this approach, process improvement and information management are most valued. Improved information flow can be achieved through process mapping and electronic information management tools that enable real time processes to be shared and analysed with the relevant departments. This will improve the visibility of information in the organisation and break down barriers between various departments which is a key ingredient to TQM.

Blend the Best Practices from the Different Methodologies

Focusing on one methodology for continuous improvement can limit progress, diminish innovation and restrain the organisation’s ability to realize its full continuous improvement potential. Use the best tool for the activity picking from Six Sigma, Lean, Kaizen, Value Stream Mapping and other techniques to deliver results. It is important to understand the tools that are required for each type of project. More often than not, Kaizen will be the very first tool you use to implement your quick successes.

Increase Customer Focus

An increase in customer focus aims at creating a system that captures customer information, correspondence, purchase history and improves collaboration with customers. This information helps your customer service department or sales team identify and target the “customer needs”. Consequently, improving the existing process in these departments and enhancing the customer experience. Many organisations, for instance, go a long way towards increasing customer focus, simply by insuring that critical customer related information is at the fingertips of their sales team. Only good quality customer service is likely to result in repeat purchases and positive referrals.

To stimulate change and make continuous improvement as an organisation strategy, the management team also needs to be committed, as they are the ones who lead and inspire project teams. Each organisation is dynamic in its behaviour. Therefore, choosing the right mix of approaches to achieve your continuous improvement goal will depend on the capabilities and resources of the team.

Conclusion

Process mapping is one of the critical steps in continuous improvement process throughout the organisation. The first step to continuous improvement is visibility of information and essentially knowing what matters most to the bottom line.

If you are interested in hearing how our services would benefit your organisation, please contact us for a free consultation.

Request a free consultation

Contact us to discuss your needs and see how we can support to reach your goal.

Recent posts

In today's digital age, businesses are constantly exposed to various cyber threats. As a result, companies must adopt a proactive approach to cybersecurity to prevent data breaches, theft, and other...

Quality management systems are essential in ensuring that organisations can deliver quality products and services consistently. The International Organisation for Standardization (ISO) developed the ISO 9001 standard to help organisations...

ISO 14001 is a globally recognised standard for environmental management systems (EMS) that helps organisations manage their environmental impact and improve their sustainability performance. Obtaining this certification demonstrates a company's...

Just a Few of Our Clients

Request a Free Consultation

Contact us to discuss your needs and see how we can support to reach your goal.